1. Clean the surface of the parts. There are many types of auto parts, complex shapes, and difficult to clean. The inner and outer surfaces of the parts are easily stained with dirt or metal debris. It is difficult to clean them with general cleaning methods. The impact of rain cleanliness on assembly quality and normal use is also It is very large, and all kinds of parts can be cleaned with compressed air.

2. Unblock blocked pipes. The passages, air passages and oil passages in the car are often blocked by solid foreign objects and are partially or completely blocked. Use compressed air in the opposite direction of the entry direction of foreign objects and fill in the compressed air, which can be quickly cleared.

3. Check for leaks. The air pipes, oil passages and cooling systems of automobiles often leak to different degrees. In order to find hidden leaks, the parts can be immersed in water or coated with soapy water, and the parts can be filled with compressed air, which can be successfully detected.

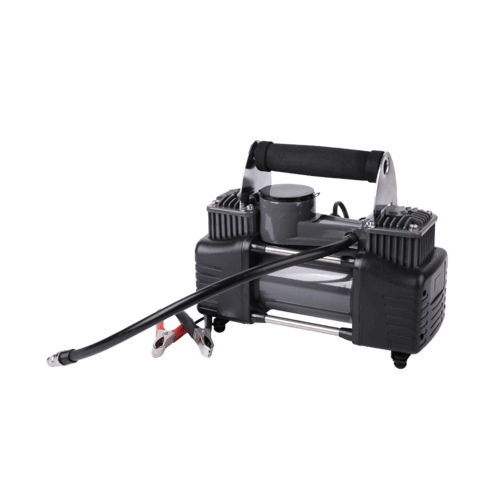

The automotive air compressor is the heart of the automotive air conditioning and refrigeration system, and plays the role of compressing and transporting refrigerant vapor. There are two types of compressors: non-variable displacement and variable displacement. According to different working principles, air conditioning compressors can be divided into fixed displacement compressors and variable displacement compressors.

4. Can be used as aerodynamic

After compressed air, it can be used as power, mechanical and pneumatic tools, as well as control instruments and automation devices, instrument control and automation devices, such as tool replacement in machining centers.

5. Can be used for gas delivery

Air compressors are also used for gas pipeline transportation and bottling, such as remote gas and natural gas transportation, chlorine and carbon dioxide bottling, etc.

6. For gas synthesis and polymerization

In the chemical industry, certain gases are synthesized and polymerized after the pressure is increased by the compressor. Such as atmosphere and hydrogen to synthesize helium, hydrogen and carbon dioxide to synthesize methanol, carbon dioxide and ammonia to synthesize urea, etc. Polyethylene is produced under high pressure.

7. For refrigeration and gas separation

The gas is compressed, cooled, expanded and liquefied by an air compressor for artificial refrigeration. This type of compressor is usually called an ice maker or ice machine. If the liquefied gas is a mixed gas, each group can be separated separately in the separation device to obtain various gases of qualified purity. For example, the separation of petroleum cracking gas is first compressed, and then the components are separated separately at different temperatures.

English

English Chinese

Chinese